The unique centripipe system provides waterproofing sealing structural reinforcement and corrosion protection for sanitary and storm culverts without trenching at significant savings.

Centrifugal concrete pipe lining.

This new process is quick non disruptive i e.

Centrifugal concrete has conducted multi million dollar projects and hundreds of thousands of square feet of concrete construction.

Epoxy and cured in place pipe.

Specializing in excavation foundation and reinforced concrete.

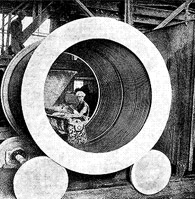

Centrifugally cast concrete pipe cccp.

Astm international has established the standards for manhole lining and will soon have a standard for cccp.

High strength factory blended cementitious liner material designed for renewal of underground concrete storm and sanitary sewer pipe wall surfaces.

The centrifugal lining process and the spinning process are typically used to install sewpercoat in ductile iron and steel pipe.

Centrifugal lining offers expertise in multiple pipe restoration processes.

Centripipe the proven engineered cccp system ap m s centrifugally cast concrete pipe system for the structural renewal of culverts and sanitary sewer pipe without backhoes repaving traffic detours flooding or hazardous construction.

Sewpercoat can also be batched and mixed in large quantities and wastewater shapes like manhole and lift station sections can be traditionally formed and cast.

No excavation efficient and at a lower cost than conventional techniques.

Whether your pipe issue is best addressed with a centrifugally cast concrete pipe system cccp or a ultra violet cured in place cipp we can provide the solution you need.

The corrugated profiled liner produced from cccp in larger pipes is an economical way to line the pipes because you are not using excess material to fill the corrugations.

Epoxy pipe lining and cured in place pipe cipp within each section the authors provide an overview of the technology.

Centrifugal lining provides cccp services from centri pipe the leading solution for cement lining large pipes.

To explore the facts about pipe lining this site organizes the discussion into two sections that correspond to the two primary technologies currently available in the marketplace for typical multifamily properties.

The bi directional packerhead method is used to install sewpercoat in large diameter concrete pipe.

Over the years we have established excellent relationships with vendors and sub contractors as well as project managers construction managers architects and engineers.

The rocla process is another method to apply a cement mortar lining inside a concrete pipe.

Centrifugally cast concrete pipe lining cccp on larger pipes can produce a liner that profiles the existing corrugations.

To 144 12 feet i d.

Has developed a system for lining repairing all types of culverts pipes shafts and tunnels from 18 i d.